We guarantee customers receive correct, rapidly, on-time, ample help and solutions. Having to pay close notice to each merchandise and detail from begin to conclude to ensure the achievements of each venture we undertake.

Consistency and Repetition: CNC machines provide steady replications of identical parts with correct specs when, making them The best Answer for mass production. In spite of complex designs, CNC machining makes sure Just about every portion remains comparable to its predecessor in visual appeal.

The collection of Directions used to drive numerical machines takes the shape of letters, quantities, and symbols. Punch playing cards and various methods were used to feed this kind of Recommendations in the machine.

While some plastic components could be crafted with injection molding, metal parts, and any complex parts exclusively use CNC machining. A number of the parts that healthcare manufacturers craft with CNC machines are:

Unilateral Tolerances: In this sort of tolerance, variation in dimensions is permitted in just one direction. The tolerance limit can possibly be previously mentioned or underneath the intended sizing.

Laptop or computer-aided design generates a computerized graphical illustration of your aspect. This representation is simple to comprehend for designers, operators, and suppliers. Having said that, the CNC machines which make the section do indirectly grasp this electronic format.

Wearing summer linens, Main govt Aleksey Bredikhin welcomed the crowd seated among the plates of area delicacies and flutes of prosecco. He paused to recognize quite a few friends who experienced traveled thousands of miles to affix the festivities in Sochi.

It's really a subtractive manufacturing system wherever the machine begins having a block and gets rid of material from it with a cutting tool. Precision machining is commonly used for making an assortment of parts that in shape and work with each other.

Serious rigidity is important for micro-Swiss turning. Though enabling us to obtain good finishes and lengthen tool daily life, Swiss turning also allows bigger speeds and shorter cycle situations for the reason that vibrations are absorbed into machine mass. Extraordinary rigidity allows Swiss turning of numerous types of materials, which includes titanium, chrome steel, valuable metals, MP35N, PEEK, Ultem, etc. It is notice to element that makes Nanotech Precision, LLC the Swiss turning corporation of choice for healthcare Swiss machining and Swiss turning.

The process also gets rid of the necessity for manual assembly and enhances the production speed in comparison with conventional solutions. When the design is finish, the component is often tested and evaluated for use in automotive applications. The hybrid manufacturing process allows firms to lower fees though producing high-quality parts promptly and efficiently.

Product expenditures might be lessened by looking at the dimensions with the blank required, and the associated fee and machinability of the bulk content (softer alloys are speedier to machine).

On top of that, precision grinding can assist develop shut-tolerance finishes on a finished product or service by eradicating modest bits of excessive product.

The requirements from the navy and defence industries are comparable to those on the aerospace industries. Rather than basic parts, these industries have to have complex machinery with the big selection of progressive materials and complex equipment they manufacture.

Health-related Units: Accuracy is in the utmost value In regards to professional medical equipment. CNC machining is here usually used to generate surgical devices, implants, and orthopaedic products, one example is.

Jaleel White Then & Now!

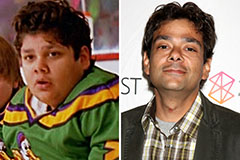

Jaleel White Then & Now! Shaun Weiss Then & Now!

Shaun Weiss Then & Now! Marla Sokoloff Then & Now!

Marla Sokoloff Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Matilda Ledger Then & Now!

Matilda Ledger Then & Now!